Avoid wasting your time and money on a bad print job. By knowing what types of printing are available to you, you can achieve stunning results on your next print project.

Clash Graphics gathered information on 7 forms of printing to help you make informed decisions when selecting the right type of printing for your next print job.

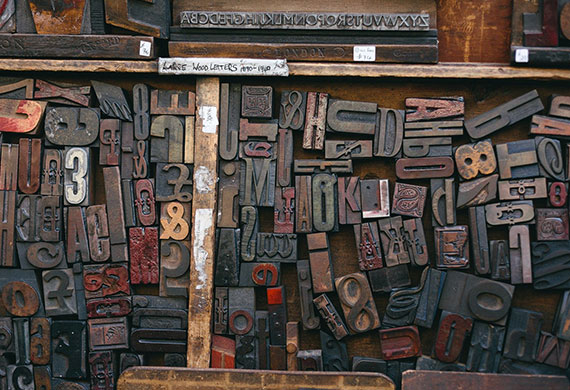

Flexography

Flexography, sometimes called flexo, is an updated version of letterpress printing. This method of printing can be used on almost any type of substrate, including:

• Label stock

• Fabric

• Metallic film

• Corrugated cardboard

• Cellophane

• Bags

• Product packaging

• Plastic

Flexography prints from a flexible printing plate that is wrapped around a rotating cylinder.

The process uses quick-drying, semiliquid inks transferred to the printing plate by rotating cylinders.

Offset Lithography (Offset)

Offset printing uses plates, frequently made from aluminum, which are used to transfer an image onto a rubber "blanket", and then rolls that image onto a sheet of paper. It's called offset since the ink is not transferred directly to the paper. Since offset presses run so efficiently once they are set up with plates and colors, offset printing is one of the best choices. Especially when more significant quantities are ordered, and provides accurate color reproduction and professional looking printing.

Digital Printing

Digital printing disposes of the need for plates, but instead uses toner for smaller printers and sometimes liquid ink in larger digital printers. Digital printing outperforms other types of printing when lower quantities are needed. Another benefit of digital printing is its flexible data capability. When each printed unit requires a unique code, name, or address, digital is the superior option.

Read about the advantages and disadvantages of digital and offset printing at clashgraphics.com/printing-tips/digital-vs-offset-printing-explained/

Screen Printing

Screen printing is a technique in which mesh is used to apply ink onto a substrate, except in specific areas made impenetrable to ink by a blocking agent. A squeegee is moved across the screen to fill the open mesh with ink. A reverse stroke causes the screen to make contact with the substrate momentarily. Contact from the reverse stroke causes the ink in the mesh to wet the substrate and be pulled from it as the screen lifts off of the substrate. Only one color is applied at a time, so to produce a multicolored product, a single screen must be produced for each color.

Find out more about screen printing at clashgraphics.com/printing-tips/screen-printing-heat-transfer-direct-to-garment-custom-t-shirts/

Wide-Format Printing

Large or wide-format printing is a medium that has been growing in popularity for advertising. Its purpose is to support maximum print roll width. The advantage of this type of printing is the ability to work with a bigger area. Wide-format printing can be used to produce banners, posters, murals, wallpapers, and billboards. This printing type is ideal for projects that require wide images, large texts, and visual or graphic-heavy designs.

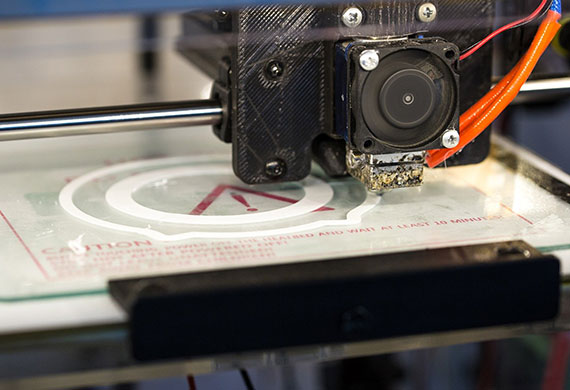

3D Printing

3D printing, also referred to as additive manufacturing, is the process of making a three-dimensional object from a digital file. 3D printed objects are made using an additive process. An additive process means that an object is created/formed by applying successive layers of material until the object is finished.

LED UV Printing

In traditional printing types, inks are typically solvent-based and dry as their chemical components evaporate. LED-UV inks dry (cure) instantly using a UV light.

The difference between UV and LED-UV is the light used to cure the ink. LED-UV generates an energy wavelength from light-emitting diodes (LED) entirely used to cure the ink. Traditional UV produces an energy wavelength from a mercury-vapor bulb that is less efficient, as only part of the wavelength is used to cure inks and/or adhesives.

Defining Your Print Project

Once you have determined which printing type fits your project best, your next determination should be the type and quality of the substrate or paper. For more detail about paper types and qualities, visit clashgraphics.com/printing-tips/paper-quality-and-type/

Regardless of how many times you’ve proofed your project before sending it to your professional printer, always request a prepress proof. A prepress proof allows you to see what the finished product will look like and allow last-minute adjustments in color and print.

Types of Printing

In this article, you discovered information about 7 types of printing and how to determine which one best suits your printing project.

By knowing what printing options are available to you, you can adjust your project as needed while being in full command of the end result.

When you are entirely reliant on others to produce your vision, you may lose valuable time and resources, waiting for them to get it right. If they ever do.

Sources:

web.tech.uh.edu/digitalmedia/materials/3350/Flexography.html

westga.edu/pubprint/offset-printing.php

printcopymail.umich.edu/copysvcs/digitalprinting.htm

wisegeek.com/what-is-screen-printing.htm

libguides.utk.edu/AVM3D_Print_Lib_Guide

flaar-reports.org/index.php/services/

Clash Graphics Print Shop Atlanta Flyer Printing

2233 Peachtree Rd NE Ste 202 Atlanta, GA 30309

(678) 235-3464