Print design remains one of the most tangible ways to communicate a brand’s message. While screens dominate our daily lives, there’s something irreplaceable about holding a beautifully crafted brochure, flipping through a well-designed magazine, or receiving a premium business card. This article breaks down everything you need to know about print design—from its definition and core principles to why it continues to play a significant role in modern marketing strategies.

Quick answer to what is print design?

Print design is the process of creating visual content and layouts on screen that will ultimately be reproduced on physical materials such as paper, cardboard, fabric, plastic, or packaging. Unlike web design or digital content creation, every decision a print designer makes is geared toward a fixed, physical size and a specific printing method.

Designers typically work in design software such as Adobe InDesign, Photoshop, or Illustrator. Still, their focus is always on how the final product will look and feel once it leaves the printer. This means accounting for factors that don’t exist in digital mediums—things like ink absorption, paper texture, and precise trim measurements.

Print design is used to create brochures, business cards, book covers, posters, packaging, magazines, menus, annual reports, event programs, and countless other printed materials. The core technical considerations that separate print from digital include:

-

CMYK color mode (cyan, magenta, yellow, and black) instead of RGB

-

300 DPI resolution for sharp, crisp output

-

Bleeds extending artwork beyond the trim edge

-

Margins keeping critical elements safely inside the cut zone

-

Trim size defining the exact final form of the piece

Beyond the technical, print design creates tangible experiences. People hold printed materials, feel the weight of the paper, notice the texture of an embossed logo, and sometimes even the smell of fresh ink on quality stock. This sensory dimension gives print a unique power that digital formats simply cannot replicate.

Despite the explosive growth of digital technology, print design remains central to branding and marketing. From luxury packaging to direct mail campaigns, businesses continue investing in print because it works.

Why print design still matters in a digital-first world

Print has been a communication staple for centuries—from early woodblock printing in China to Gutenberg’s press in the 15th century to today’s high-speed offset and digital presses. The medium has evolved dramatically, but its relevance hasn’t faded. Businesses, nonprofits, educational institutions, and governments still rely on print to reach audiences in ways that digital channels cannot.

One of print’s greatest strengths is its ability to cut through digital noise. A well-designed postcard, catalog, or magazine doesn’t compete with push notifications, banner ads, or overflowing email inboxes. It occupies physical space and demands a different kind of attention.

Here’s why print design remains relevant today:

-

Higher recall and trust: Studies consistently show that printed materials generate stronger memory retention. Direct mail open and response rates are much higher compared to email open rates. Additionally, a large share of consumers report trusting print ads more than digital ads.

-

Brand authority and permanence: Annual reports, trade show displays, product packaging, and in-store signage physically occupy space in offices, homes, and retail environments. A conference booklet might sit on someone’s desk for months, continuing to market long after a promotional email has been deleted.

-

Local reach: Restaurants, clinics, real estate agents, schools, and small businesses still depend heavily on menus, flyers, yard signs, and mailers to connect with nearby audiences who may not be actively searching online.

-

Sensory engagement: Print offers creative possibilities that screens cannot—textured stocks, foil stamping, soft-touch finishes, and even scent. These tactile elements create memorable brand experiences.

-

Complementary to digital: Rather than competing with digital, print now works alongside it. QR codes on postcards drive traffic to landing pages. Catalogs inspire online purchases. Event programs link to mobile apps. The best modern campaigns seamlessly integrate print and digital.

The global print market exceeded half-a-trillion in 2025 and is projected to grow annually through 2030, driven largely by packaging demand. Print isn’t dying—it’s evolving.

Key types of print design

Most print projects fall into a few practical categories: marketing materials, stationery and branding collateral, publications, packaging, and environmental or large-format graphics. Understanding these categories helps you plan content, choose appropriate file formats, and budget your print runs more effectively.

Each category has its own design considerations, production techniques, and typical use cases. Let’s break them down.

Marketing and promotional materials

Marketing materials are among the most common print projects. They’re designed to grab attention, communicate a message quickly, and prompt action—whether that’s visiting a store, attending an event, or making a purchase.

Common formats include:

-

Flyers and leaflets: A5 or US letter handouts used for local events, limited-time sales, restaurant openings, and community announcements. Design focus: bold headlines, clear hierarchy, and a single call to action.

-

Brochures: Bi-fold, tri-fold, and gatefold formats used by real estate agents, tourism boards, healthcare providers, and trade show exhibitors. These allow more space to tell a story while remaining portable.

-

Posters and banners: From small A3 prints in coffee shops to large-format concert announcements and festival graphics. Legibility from typical viewing distances is critical—what works at arm’s length fails at 20 feet.

-

Postcards and direct mail: Promotions mailed to homes, event invitations, fundraising appeals, and political campaign pieces. Direct mail continues to outperform many digital channels in response rates, with studies showing a large percentage of recipients take action within a week.

Effective marketing materials prioritize visual hierarchy, ensuring the most important information (headline, offer, date) stands out immediately. A cluttered flyer with too many competing elements will be ignored.

Stationery, identity, and brand collateral

Print design reinforces brand identity through everyday touchpoints. The business card you hand someone, the letterhead on your proposals, the folder holding your presentation—these pieces shape how people perceive your organization.

Core stationery items include:

-

Business cards

-

Letterheads and compliment slips

-

Envelopes (standard and custom sizes)

-

Branded folders and presentation materials

-

Notepads and sticky notes

Event-related stationery extends to invitations, save-the-date cards, RSVP cards, place cards, and thank-you notes for weddings, conferences, and product launches.

Smaller branded pieces also matter: stickers, labels, hang tags for clothing, membership cards, loyalty cards, and gift certificates. Consistency in logo usage, color palette, and typography across all these items builds recognition and trust—not over weeks, but over years of repeated exposure.

Publication and editorial design

Publication design covers long-form, multi-page works where layout and typography directly affect the reading experience. The multi-page layout and reading experience domain is where print designers become experts in grids, margins, and the subtle art of guiding a reader through pages of content.

Key formats include:

-

Books: Novels, textbooks, coffee-table art books, and reference guides. Page margins, type size, and line length all affect reading comfort during extended sessions.

-

Magazines and journals: Quarterly company publications, alumni magazines, industry journals, and consumer magazines. These balance text-heavy articles with photography, illustrations, and advertising.

-

Corporate reports: Annual reports, sustainability reports, investor presentations, and white papers. These documents represent organizational credibility and require polished, professional design.

Publication designers rely on grid systems to maintain consistent alignment across dozens or hundreds of pages. Running headers, footers, page numbers, captions, and pull quotes all require careful attention. The goal is invisible design—layouts so well-organized that readers focus entirely on the content.

Packaging and label design

Packaging design sits at the intersection of structural engineering and visual communication. Print designers must consider not just how something looks, but how it folds, protects its contents, and functions on a retail shelf.

Packaging applications include:

-

Boxes, sleeves, and cartons for consumer goods

-

Bottles, cans, and pouches for beverages and food

-

Mailer envelopes and shipping boxes for e-commerce

-

Blister packs and clamshells for electronics and accessories

Designers often create dielines—flat templates showing folds, flaps, glue areas, and panel boundaries. Understanding how a 2D design becomes a 3D form is essential.

Labels and wraps apply to products like wine bottles, craft beer cans, skincare products, and specialty foods. Beyond aesthetics, packaging must also accommodate legal and practical requirements, including barcodes, nutritional information, ingredient lists, safety icons, and recycling symbols. A beautiful label that lacks required information never makes it to market.

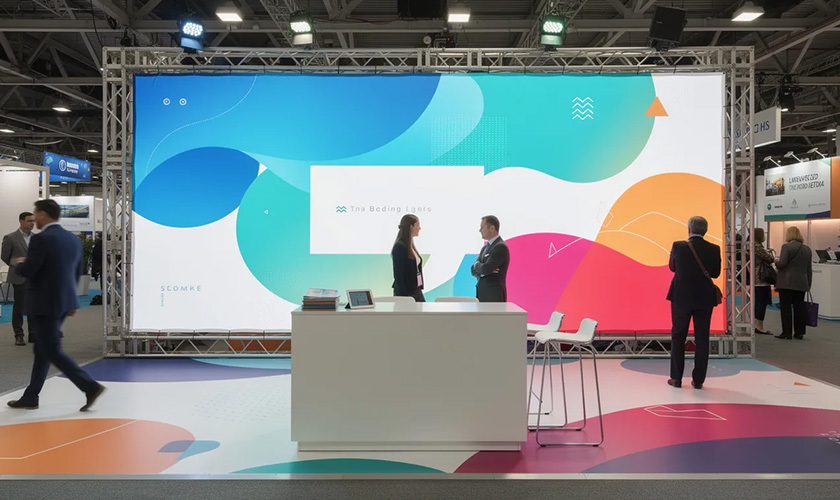

Environmental and large-format graphics

Environmental graphics take print design into physical spaces. Rather than handheld pieces, these designs guide, inform, and brand entire environments.

Applications include:

-

Signage and wayfinding: Systems for retail stores, corporate offices, hospitals, museums, and university campuses. Door signs, directional arrows, floor maps, and informational displays.

-

Trade show and event graphics: Pull-up banners, pop-up walls, backdrops, table covers, and fully branded booth environments.

-

Outdoor advertising: Billboards, bus shelter ads, building wraps, and transit advertising on buses, trams, and subway systems.

Design considerations shift dramatically at this scale. Billboards may be viewed for only 3-5 seconds from a moving vehicle, requiring ultra-simple messaging and high contrast. Large-format prints can use lower resolution (sometimes 150 DPI or less) because viewing distances are measured in feet, not inches.

Core principles and elements of effective print design

Print design blends timeless visual principles with technical precision unique to physical production. Whether you’re creating a tri-fold brochure or a 200-page catalog, the same fundamental elements and principles apply.

This section covers typography, color, layout, image quality, file preparation, and production choices. These basics form the foundation for any successful print project—and understanding them separates professional results from amateur attempts.

Typography and readability

Typography matters more in print than almost anywhere else. Readers can’t pinch-to-zoom on a printed page. The layout is fixed. Every type decision is permanent once ink hits paper.

Key considerations for print typography:

-

Typeface selection: Serif fonts (like Garamond or Times) traditionally work well for long-form body text in books and reports. Sans-serif fonts (such as Helvetica or Open Sans) often suit headlines, captions, and modern marketing materials.

-

Size and leading: Body text typically ranges from 9-12 points, depending on the typeface and medium. Leading (line spacing) should be 120-145% of the type size for comfortable reading.

-

Line length: Optimal line length runs 50-75 characters. Lines that are too short create choppy reading; lines that are too long exhaust the eye.

-

Hierarchy: Use size, weight, and positioning to distinguish headings, subheadings, body copy, captions, and calls to action. Readers should instantly understand what to read first.

Common pitfalls include setting body text too small (under 8 points), cramming lines too tightly, overusing decorative fonts, and failing to create sufficient contrast between text and background.

Color theory, CMYK, and spot colors

Color operates differently in print than on screen. Digital displays use additive RGB color (red, green, and blue light combining to create colors). Print uses subtractive CMYK color (cyan, magenta, yellow, and black inks layered on paper).

Practical implications:

-

All designs must be converted to CMYK before sending to a printer. RGB files will print, but colors may shift significantly—often appearing duller or muddier than expected.

-

CMYK values define ink percentages. A deep blue might be C100 M60 Y0 K10, meaning 100% cyan, 60% magenta, no yellow, and 10% black.

-

Pantone colors (spot colors) provide exact color matching across different print runs and materials. Brands with strict color standards often specify Pantone values to ensure consistency, whether printing business cards in January or packaging in July.

Colors almost always appear more vibrant on a backlit screen than on printed paper. Soft proofing (previewing CMYK output on screen) and ordering physical proofs before large runs helps avoid expensive surprises.

Layout, grids, and composition

Professional print layouts rely on invisible structure. Grids keep elements aligned across pages and panels, creating visual consistency that readers feel, even if they can’t articulate it.

Grid fundamentals:

-

Column grids: Divide the page into vertical columns for text and image placement. Common in magazines, newspapers, and catalogs.

-

Modular grids: Add horizontal divisions, creating a matrix of cells for more complex layouts.

-

Margins and gutters: Margins define outer boundaries; gutters provide space between columns or between facing pages in bound documents.

Beyond structure, effective composition guides the eye through a deliberate visual path. The headline grabs attention first; subheadings and imagery draw the reader deeper; and body copy provides detail. White space—intentionally empty areas—prevents crowding and gives designs room to breathe.

Overcrowded layouts are the most common mistake in amateur print design. When everything shouts for attention, nothing gets heard.

Resolution, DPI, and image quality

Print quality depends heavily on image resolution. Low-resolution graphics that look fine on screen become pixelated, blurry messes in print.

Understanding DPI and resolution is critical; this is the standard specification:

-

300 DPI/PPI at final print size for high-quality offset printing

-

Images should be prepared at this resolution before placement in layout software

-

Enlarging low-resolution images doesn’t add quality—it just makes pixels bigger

Large-format prints (billboards, building wraps) can use lower effective resolution because they’re viewed from greater distances. A billboard might use 50 DPI and still appear sharp from the road.

Never grab images from websites and drop them into print layouts. Web graphics are typically 72-150 PPI—fine for screens, disastrous for print. Either source high-resolution originals or accept that the finished design will disappoint.

File formats, bleeds, and print-safe margins

Proper file preparation directly affects whether your design prints correctly. Sending the wrong format or omitting technical specifications can delay production and lead to costly reprints.

Essential file prep:

-

Final format: Print-ready PDFs (often PDF/X standards) with fonts embedded and images at full resolution. While designers work in native file formats like INDD, AI, or PSD, printers typically request PDFs.

-

Bleed: An extension of artwork beyond the trim edge—usually 3mm (0.125 inches) on all sides. Any background color, image, or graphic that touches the edge must extend into the bleed area. This prevents white slivers from appearing if the cutting alignment shifts slightly.

-

Safe margins: The inner zone where all critical text and logos must remain. Typically 3-5mm inside the trim line. Nothing important should approach the cut edge.

Forgetting bleeds or placing important elements too close to trim lines are among the most frequent causes of print production problems.

To ensure proper bleed, visit How to Add Bleed in Photoshop and How to Add Bleed in Illustrator.

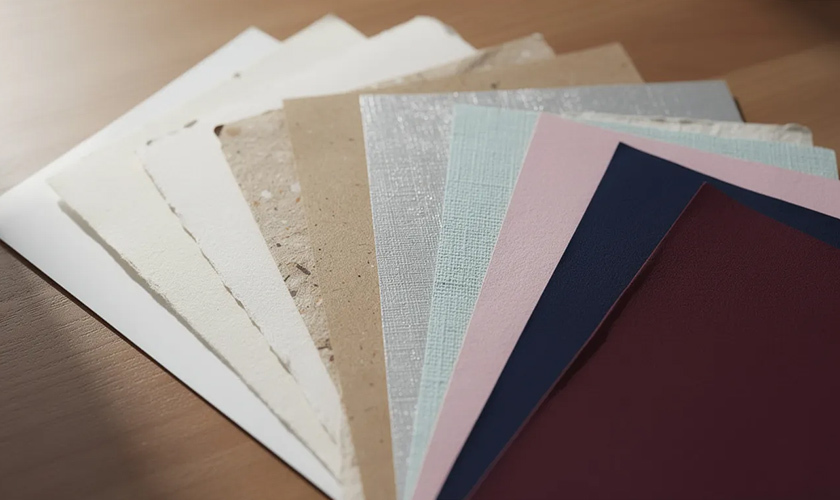

Paper, finishes, and production choices

The same design can feel completely different depending on the paper type, stock, and finishing techniques. Material choices transform a generic brochure into a premium piece—or undermine an otherwise strong design.

Paper considerations:

-

Weight: Measured in GSM (grams per square meter) or pounds. Office paper runs around 80 GSM; business cards typically use 300-400 GSM stock.

-

Coating: Gloss coatings create vibrant colors and shiny surfaces. Matte and silk finishes offer softer, more subdued appearances. Uncoated stocks feel more natural and tactile.

-

Texture: Smooth, linen, laid, and specialty textures each create distinct impressions.

Special finishes add further dimension:

-

Foil stamping: Metallic or colored foil applied to specific areas

-

Embossing/debossing: Raised or recessed designs pressed into the paper

-

Spot UV: Glossy varnish applied to selected elements while the rest remains matte

-

Soft-touch lamination: A velvety, tactile coating

These production choices affect cost, turnaround time, and color appearance. Glossy stocks make colors pop; uncoated papers absorb more ink and appear more muted. The key is matching production choices to project goals and budget—ideally by consulting with your printer early in the design process.

Print design vs. digital design: how they differ and overlap

Print design and digital design share fundamental principles—typography, color theory, composition, and hierarchy apply to both. But the medium changes everything about constraints and creative possibilities.

Key differences include:

-

Fixed vs. responsive: Print layouts are fixed to specific dimensions. A poster is exactly 24×36 inches. Digital interfaces must adapt to a wide range of screen sizes, from mobile phones to desktop monitors.

-

Color modes: Print uses CMYK; screens use RGB. Designs must be converted appropriately, and colors that look identical on screen may diverge significantly in print.

-

Resolution requirements: Print demands 300 DPI for quality reproduction. Digital images are measured in pixels and can vary widely based on display and context.

-

Interactivity: Print is static. Digital design includes clicks, taps, scrolls, hover states, animations, and video. A printed brochure can’t play a video—but it also can’t crash, load slowly, or get blocked by an ad blocker.

-

Permanence: Once printed, a design cannot be updated. Errors require reprinting. Digital content can be revised instantly at minimal cost.

Where they overlap:

Many modern projects require both print and digital deliverables. A product launch might require printed packaging, point-of-sale displays, trade show banners, social media graphics, email templates, and a landing page. Graphic designers increasingly work across both mediums, adapting a single visual system to different technical requirements.

The smartest approach treats print and digital as complementary channels. A direct mail piece drives recipients to a website. A printed catalog inspires online purchases. A poster includes a QR code linking to augmented reality content. Rather than choosing between media, effective brand communication leverages each for its unique strengths.

Best practices for creating successful print designs

Before sending any project to production, run through these practical checkpoints. They’ll help you avoid common mistakes and ensure your printed materials look as good in hand as they did on screen.

Define purpose and target audience first

Every print project should answer clear questions: What should the recipient do after seeing this piece? Visit a website? Attend an event? Remember the brand? Clarity on purpose shapes every design decision.

Confirm format and specifications early

Decide on dimensions (A4 flyer, DL brochure, US letter tri-fold, A2 poster) and verify requirements with your printer before designing. Different printers have different templates, bleed requirements, and file format preferences.

Keep layouts focused

Resist the urge to fill every inch of space. White space improves readability and draws attention to what matters. This is especially critical in small formats like business cards or postcards, where crowding quickly becomes overwhelming.

Proof rigorously

Check spelling, dates, prices, phone numbers, email addresses, and QR codes. Have at least one other person review before printing. Errors in print are permanent and expensive.

Print test copies

Even a basic office printer can reveal layout problems—incorrect margins, awkward text breaks, or low-resolution images—before you commit to a full production run.

Collaborate with your printer

Involve production partners early. They can confirm bleed sizes, recommend paper stocks within budget, explain finishing options, and flag potential issues before they become costly mistakes.

Consider sustainability

Environmental impact matters to many audiences. Options include recycled papers, FSC-certified stocks, soy-based inks, and efficient print runs that minimize waste. Some waterless printing techniques reduce water use significantly over their traditional counterparts.

How print design fits into modern marketing and branding

Print design doesn’t exist in isolation. It’s a vital part of broader brand and marketing strategies, reinforcing visual identity across countless touchpoints—from the box a product arrives in to the business card exchanged at a conference.

Consistent print materials build recognition. When your brochures, stationery, packaging, and signage all share the same typography, colors, and design language, audiences instantly recognize your brand. This consistency compounds over time, building trust and familiarity.

Print also drives digital actions. QR code marketing on postcards link to landing pages. Personalized URLs on direct mail track campaign responses. Printed coupons are redeemed online. The line between physical and digital continues to blur, with augmented reality markers increasingly appearing on print pieces to unlock interactive experiences.

Currently, omnichannel campaigns are standard practice. Graphic designers create visual systems once, then adapt them for posters, flyers, catalogs, social media posts, email banners, and web ads. Understanding both print and digital requirements is no longer optional; it’s expected.

Print often signals investment and seriousness. A hardcover company history communicates permanence. A carefully produced catalog suggests quality products. Premium product packaging elevates perceived value. Studies indicate professionally printed materials can increase perceived brand value.

Understanding what print design is—its technical requirements, creative possibilities, and key differences from digital—helps businesses and designers create more memorable, effective communication. In a world flooded with fleeting digital impressions, something you can hold in your hands still carries remarkable power.

Whether you’re planning your first brochure or overseeing a complete brand identity system, the basics covered here provide a foundation for print projects that look professional, communicate clearly, and deliver results.

(678) 235-3464

To view the original version on Clash Graphics, visit: https://www.clashgraphics.com/printing-tips/what-is-print-design/