The appearance of printing projects depends on the right combination of varied printing paper and customization options. However, knowing and choosing the best options may be challenging because there are so many options to choose from. Most buyers make mistakes because of the confusing multitude of paper types. Here, we will explain the available paper weight choices and how to tell the difference between each of them.

The appearance of printing projects depends on the right combination of varied printing paper and customization options. However, knowing and choosing the best options may be challenging because there are so many options to choose from. Most buyers make mistakes because of the confusing multitude of paper types. Here, we will explain the available paper weight choices and how to tell the difference between each of them.

Choosing Your Printing Paper

To most consumers, paper is either flimsy or firm. Although, there are numbers and metrics used to signify the thickness and sturdiness of paper.

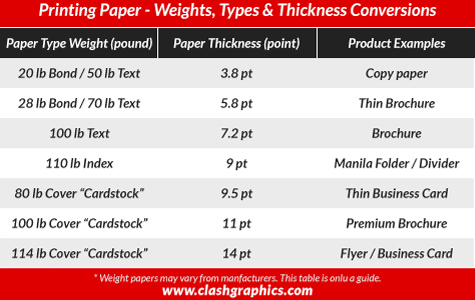

A good rule of thumb is: the greater the weight or point, the more sturdy and durable your material will be. Below are various paper weight units of measurement and their definition.

Paper Weight and Measurement Definitions

Since all manufacturers don’t use the same metric, our team at Clash created a quick reference for the most commonly used paper types, weights and measures.

Learn this basic unit of paper weight measurement.

Learn this basic unit of paper weight measurement.

Pound – Distinguishes how many pounds 500 sheets of a specific paper grade weighs. Each respective paper grade has an industry standard size.

Point – Refers to the thickness of an individual sheet when measured with a device that measures micrometers, or thousands of an inch.

Below are the more popular paper weights.

Text – This paper can be referred to as “offset”, and has a wide range of uses.

Bond – Uncoated bond stock, often called “writing” paper, is most often used in office printer and copy machines.

Cover – These stocks are mostly rigid and not easily folded. Cover stock paper is frequently used on publication covers, business cards, folders and postcards

Paper Coating

Paper coating adds a tactile and visual appeal to printed materials. These coatings are flexible in their application. They can be used on the entire surface, or a certain part of the paper to highlight your logo or company mark for example.

UV Coating: (Ultra Violet): The solvent-free UV coating is a lustrous, glossy, very protective coating that provides a chemical and abrasive resistant hard finish. It may be used strategically to make a logo or picture stand out or used on an entire surface.

Aqueous: This water-based coating is thinner than UV coating. It protects surfaces from dirt, fingerprints, and scratches with its medium glossy finish. It is mostly used on brochures and postcards as well as business cards, protecting them through their journey in mails and deep pockets.

Paper Types

The right paper type can make your printing project really stand out. With choices ranging from gloss to dull, satin and matte, you can greatly improve the look of your project by simply selecting the right type. Get familiar which each type below:

Gloss – Just like a photograph, this appears as a glossy surface.

Satin – Coming halfway between gloss and matte, it enhances full-colour graphics even while preserving eligibility of the readable text. And it still looks shiny and attractive

Matte – This kind of finish is perfect for text-heavy documents. It appears smooth yet not as shiny as the other kinds of finish. It also removes fingerprints.

Uncoated – Stock that has not been coated with any sealant. UV or Aqueous coating cannot be applied to this type of paper.

Custom Printing Options That Stand Out

Your materials must be effective in conveying your message, but a unique finishing solution is a simple way to make your project more appealing to your audience. Below are some of the popular customizations you may choose to incorporate in your next project.

Embossing – Love to feel the designs and texts as you run your fingers over the paper? Using high pressure, embossing uses a specially-made die to create these impressions.

Metallic Ink – Using ink with fine reflective metallic particles create a look you won’t see around. To get that shiny and lustrous look, gold and silver are the go for.

Foil Stamping – By using heated die to stamp foil to paper, you can create design that shimmer and add texture to certain texts or graphics.

Die Cut – From straight out of the normal curves to perfect circles to the outline of imagines and company designs, die cutting helps create an infinite range of contours.

There are plenty of printing customization combinations. Knowing paper weight thickness, coating types, and finishing options will help ensure your next printing project is a success.

Clash Graphics Print Shop Atlanta Flyer Printing

2233 Peachtree Rd NE Ste 202 Atlanta, GA 30309

(678) 235-3464

To view the original version on Clash Graphics, visit: http://www.clashgraphics.com/printing-tips/printing-paper-weight-thickness-conversions-guide/