Large format printing refers to the production of graphics significantly larger than standard office or commercial prints, typically starting at about 18 inches wide and extending to 100 inches or more. This category includes banners, posters, signs, trade show displays, vehicle wraps, and building graphics—all produced on specialized large format printers that standard printers simply cannot match. The technology enables businesses to create high-impact visual communication that commands attention in retail spaces, at events, billboards, and across outdoor environments.

For businesses and brands, large-format printing delivers high-visibility marketing at a fraction of the cost of TV or radio advertising. A single well-placed vinyl banner or window graphic can generate thousands of impressions daily, working around the clock to attract attention and reinforce brand identity. Whether you need indoor promotional materials or durable outdoor signage that withstands harsh weather conditions, large format offers an ideal solution for campaigns of any scale.

Consider a retailer preparing for a major holiday sale. Instead of relying solely on digital marketing and ads that disappear after a scroll, they invest in 2-meter-wide window graphics showcasing their biggest discounts. These floor graphics and window decals draw attention from passing foot traffic for weeks, creating a lasting impression that drives customers through the door. This scenario illustrates exactly why wide-format printing has become essential for business marketing.

The printing process uses inkjet technology to produce high-quality prints on various materials—vinyl, fabric, paper, canvas, and rigid substrates such as foam board and acrylic. Modern systems commonly use water-based, eco-solvent, or UV-cured inks to create sharp images with excellent color reproduction. The result is graphics that make text readable from a distance and produce vibrant, high-resolution output suitable for everything from intimate gallery prints to massive building wraps.

Large-format printing services bridge the gap between digital design and physical presence. In crowded environments where businesses compete for attention, oversized graphics deliver the big impact that small-format marketing materials cannot achieve.

Large Format Printing 101

Retailers, event organizers, construction firms, schools, and nonprofits rely on large-format printing to solve a simple problem: standard printers can’t produce graphics large enough to be seen from across a room—much less across a street. When you need a trade show backdrop, construction site hoarding, or a retail display that stops shoppers in their tracks, wide-format printing is the only practical option.

The difference between standard office printing and large format printing comes down to scale and capability. Office devices typically max out at A3 or 11x17 inches—fine for reports and flyers, but useless for a 3-meter exhibition wall. Large format printers handle rolls and sheets from roughly 18 inches up to 10 feet or more in width, with virtually unlimited length for roll-fed materials. These devices also print on a far wider range of substrates, from standard paper to vinyl banners, fabric, and rigid boards.

The basic workflow moves from design creation through to the finished product in a fairly straightforward sequence. Designers create artwork using vector graphics for logos and line art or high-resolution raster images for photography. Files are then prepared with correct dimensions, bleed areas, and color profiles before being processed through RIP (Raster Image Processing) software. The printer outputs the graphic onto rolls or rigid boards, and finishing steps complete the job—trimming, adding grommets or hems for hanging, applying lamination for durability, or mounting onto display hardware.

From a cost and efficiency standpoint, large-scale printing often makes more sense than producing multiple smaller panels. A trade show backdrop printed as a single 3-meter-wide panel requires less installation time and looks more professional than several A3 sheets taped together. At volume, cost per square foot decreases significantly, and turnaround times for digital printing are typically measured in hours or days rather than weeks.

What Is Large Format Printing? (Technical Breakdown)

The term “large format” serves as an umbrella term for several distinct printer categories, each designed for different needs. Understanding these categories helps you specify the right equipment and communicate your project requirements clearly to print providers.

Production printers represent the high-volume end of the spectrum. These devices excel at producing long runs of posters, direct mail pieces, and marketing materials at resolutions typically around 1200 dpi or higher. They handle paper sizes larger than SRA3 and can churn through thousands of sheets efficiently. If you need 5,000 identical posters for a concert tour or a high-volume run of promotional flyers, production print systems deliver the throughput and consistency required.

Wide format printers—often called plotters in technical environments—handle graphics starting around 24 inches wide and extending to 60, 72, or even 126 inches. The architecture, engineering, and construction industry relies heavily on these devices for CAD drawings, technical blueprints, and construction plans. AEC professionals need precision line reproduction and accurate scaling, so format printers in this category prioritize sharp lines and consistent output over photographic color reproduction.

Flatbed printers represent a different approach entirely. Instead of feeding flexible media through rollers, these devices use a vacuum table to hold rigid substrates in place while print heads travel overhead. This enables direct printing on foam board, acrylic, wood, glass, and corrugated plastic without requiring pre-coating. Real estate signs, point-of-sale boards, and dimensional displays are often produced by flatbed systems.

Modern systems across all categories commonly use UV-curable, latex, or eco-solvent inks. UV ink cures instantly under UV light, creating a durable film that adheres to virtually any surface. Latex inks use heat to fuse polymer particles into a flexible, weather-resistant layer. Eco-solvent printing inks etch into vinyl and plastics for outdoor durability while producing lower emissions than traditional solvent formulations. The choice between these technologies depends on substrate compatibility, indoor or outdoor use, and expected lifespan.

What Is the Difference Between Large Format and Wide Format Printing?

Many people use “large format” and “wide format” interchangeably, which can cause confusion when specifying print jobs or discussing equipment capabilities with vendors. While the overlap is significant, understanding the distinction helps you communicate more precisely about your requirements.

The typical industry convention draws the line based on print width. Wide-format generally refers to devices that print from about 24 to 100 inches in width, whether roll-fed or sheet-fed. Large format, meanwhile, serves as a broader category for anything larger than standard office sizes—sometimes defined as over 18 inches, sometimes over 36 inches, depending on who you ask. The boundaries are not standardized across all manufacturers and providers.

In practical terms, all wide-format jobs qualify as large-format, but not every large-format job is wide-format. A 2.4-meter (8-foot) trade show backdrop printed on a roll-to-roll printer clearly falls into wide format territory. However, a high-volume production run of 19x27 inch posters on a sheet-fed production press counts as large format printing but would not typically be called wide format since it does not require wide format printers to produce.

The simplest way to think about it: if the graphic is too big for an office printer but under about 36 inches wide, it is large format. If it exceeds roughly 36 inches and requires specialized wide format printers, it is both large format and wide format.

When requesting quotes or evaluating providers, specifying exact dimensions and quantities matters more than using the correct terminology. However, understanding these distinctions helps clarify equipment capabilities and ensures you’re making a fair comparison when evaluating large-format printing services.

Who Can Benefit from Large Format Printing?

Large format printing serves virtually any organization that needs to communicate visually in physical spaces, whether for temporary promotions or permanent installations. The technology spans industries from retail and hospitality to education and healthcare.

Retail and shopping centres are among the largest customer segments. Window graphics promoting seasonal sales, hanging banners announcing new arrivals, and floor graphics guiding customers through stores all rely on large-format output. A clearance sale event might feature 3-meter-wide window decals showcasing discount percentages, while floor decals direct traffic flow during busy periods. Retail displays built from rigid printed panels create eye-catching product presentations that grab attention and influence purchasing decisions.

Offices, corporate campuses, and industrial facilities use large format for both functional and branding purposes. Wall graphics transform bland corridors into branded experiences, while wayfinding signs help visitors navigate complex buildings. Safety signage meets regulatory requirements while reinforcing corporate identity. Reception areas feature large printed panels that create a professional first impression for customers and job candidates alike.

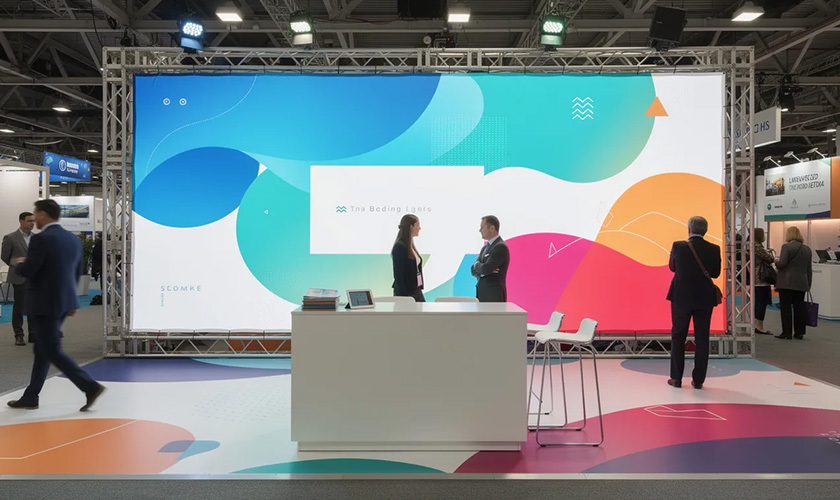

Events and trade shows drive significant demand for large-format printing. Pull-up banners provide portable branding that travels from venue to venue. Backdrops create professional settings for photography and presentations. Step-and-repeat banner walls display sponsor logos for media coverage. Directional signage guides attendees through conference centres. A single exhibitor might require dozens of printed pieces ranging from table wraps to overhead hanging displays.

Additional sectors extend the reach of large-scale printing even further. Educational institutions print campus maps and event banners. Museums produce exhibition graphics and informational panels. Real estate agencies display property signs and development hoardings. Hospitality businesses install outdoor flags and lobby graphics. Healthcare facilities communicate wayfinding information and health messaging. The common thread is the need to deliver visible, readable information in spaces where standard printers simply cannot reach.

Large Format Printing Opportunities and Typical Applications

Large-format printing delivers value wherever large, readable graphics are needed in high-traffic or large spaces. The range of applications spans temporary promotional materials to permanent architectural installations, indoor point-of-sale displays to outdoor signage designed to withstand years of exposure.

Outdoor applications represent some of the most visible uses of grand format printing. Billboards along highways deliver continuous brand exposure to thousands of drivers daily. Building wraps transform construction sites into branded marketing real estate. Fence banners turn temporary barriers into promotional surfaces. Vehicle wraps on cars, vans, and buses create mobile advertising that travels through city streets, generating impressions wherever the vehicle goes. These outdoor uses require durable materials and inks that resist fading in harsh weather.

Indoor applications often prioritize visual impact and print quality over weather resistance. Point-of-sale displays near checkout counters promote special offers and impulse purchases. Exhibition panels present information in galleries and corporate lobbies. Wall murals add personality to restaurants, offices, and retail environments. Menu boards in quick-service restaurants showcase products with appetizing photography. Window decals transform glass surfaces into branding opportunities visible from both inside and outside.

Specialized formats require additional expertise in viewing distance, lighting, and mounting hardware. Floor graphics must withstand foot traffic while remaining visible and slip-resistant. Hanging fabric banners need reinforced hems and proper weight distribution. Pop-up displays require precise cutting and folding to fit proprietary frames. Lightbox films must transmit light evenly while maintaining color accuracy. Each application presents unique technical requirements beyond simple printing.

Not every printer can handle all substrates, sizes, or applications. A provider specializing in retail displays may not offer vehicle wrap printing, while a technical plotter shop focused on AEC drawings may lack the color management expertise for high-end photography. Matching printer capabilities—width, ink type, compatible materials, and finishing options—to your intended product range helps ensure high-quality results.

Can You Use Photos in Large Format Printing?

Yes, modern large-format printers routinely produce photographic-quality graphics suitable for both commercial marketing and personal display. The technology has advanced to the point where large prints can rival traditional photographic processes in color accuracy, tonal range, and detail.

Achieving excellent photo results requires attention to source file quality and proper scaling. High-resolution images work best—300 pixels per inch at final size for close-viewed pieces like gallery prints. At the same time, graphics viewed from a distance can use lower resolutions without visible quality loss. Correct color profiles ensure that screen colors translate accurately to print media. Many photographers work in Adobe RGB or sRGB color spaces, which RIP software then converts to the printer’s specific output profile.

Practical applications for large-format photographic work span commercial and personal projects. Gallery-style canvas prints showcase fine art and photography at impressive scales. Corporate offices install large photographic murals featuring landscapes, cityscapes, or product imagery. Retail windows feature high-impact product photography scaled to 2 meters or more. Real estate displays present property images at sizes that invite close inspection of details.

Professional print providers can advise on file preparation, sharpening techniques, and proofing processes to avoid pixelation, color shifts, and loss of detail at large sizes. Many offer soft proofing on calibrated monitors or small test prints before committing to expensive large runs. For color-critical work like branded photography or fine art reproduction, these quality assurance steps are essential investments.

What Are Some Common Examples of Large Format Printing?

Large-format printing encompasses a wide range of products designed to capture attention and convey information quickly. From temporary promotional materials to permanent installations, the category includes virtually any printed graphic too large for standard office equipment.

Posters and hanging banners serve as workhorses for promotions, film releases, concerts, and local events. A cinema might display 1.5-meter-tall movie posters promoting upcoming releases, while a concert venue hangs fabric banners announcing upcoming performers. These materials are typically printed on large sheets or rolls exceeding standard office dimensions and may include mounting hardware for display.

Trade show materials transform bare exhibition stands into branded environments. Full-size back walls spanning 3 meters or more create professional backdrops for product demonstrations and media interviews. Pop-up displays use tension frames with printed fabric or vinyl skins that pack into portable cases. Fabric tension systems stretch printed graphics over aluminium frames for lightweight, crease-free presentations. Table wraps turn standard folding tables into branded surfaces. Together, these materials communicate professionalism and attract attention in crowded environments.

Exterior signage and building graphics must withstand exposure while remaining legible from a distance. Fascia signs identify businesses along busy streets. Construction hoardings protect work sites while promoting future developments. Site identification boards help visitors locate entrances and parking. Grand format printing on mesh materials allows wind to pass through while maintaining visual impact on building wraps.

Some oversized pieces exceed the maximum printer width and must be printed in sections for on-site joining. Tiled wall murals spanning entire office floors require precise alignment during installation. Multi-panel backdrops for major events may arrive as several rolls that installers join seamlessly using overlapping edges and careful registration. Understanding these production realities helps you plan projects that push the boundaries of scale.

How Does Large Format Printing Work?

The large-format printing process follows a digital workflow from design through finished product. Artwork is prepared on a computer using design software, processed through RIP software that translates the file into printer instructions, and output onto wide rolls or rigid boards using CMYK inks—sometimes supplemented with additional colors for expanded gamut or special effects.

Material selection plays a central role in the process and depends heavily on intended use. Vinyl dominates outdoor signage for its durability and weather resistance. Mesh materials allow wind to pass through large building wraps without creating dangerous sail effects. Fabric produces soft signage for trade shows and interior displays. Paper suits indoor posters and short-term promotions. Rigid substrates like PVC foam board and aluminium composite panels create self-supporting displays for point-of-sale applications. Each material interacts differently with ink, affecting color reproduction, durability, and finishing options.

Inkjet printing typically uses inkjet technology, with print heads jetting fine droplets to build the image in multiple passes. UV-curable inks cure instantly under UV light, forming a solid film that adheres to a vast range of materials, including glass and metal. Solvent and eco-solvent inks etch into vinyl for outdoor durability. Latex inks use heat to fuse polymer particles into flexible, weather-resistant layers. Dye sublimation transfers ink into polyester fabric through heat, creating vivid, wash-resistant graphics for flags and soft signage. The choice between ink technologies affects color gamut, durability, substrate compatibility, and environmental considerations.

Post-print finishing transforms raw output into usable products. Prints may require drying time or UV curing before handling. Trimmers and cutters bring pieces to final dimensions, often with automated contour cutting for complex shapes. Grommets, hems, and pole pockets enable hanging. Lamination adds scratch resistance and UV protection for outdoor use. Mounting attaches flexible prints to rigid backings. Packaging protects finished pieces during shipping and storage. Each finishing step adds cost but increases durability and functionality.

Designing for Large Format Printing

Designing for large-scale requires attention to resolution, readability, and color that goes beyond typical digital or small-format print work. The final piece must be effective when viewed from the intended distance, whether that is arm’s length in a gallery or 50 meters across a car park.

Vector graphics are essential for logos, line art, and text elements that must remain crisp at sizes up to 5 meters wide. Unlike raster images that pixelate when scaled, vector graphic files describe shapes mathematically and render at any size without quality loss. Common vector formats include AI, EPS, and PDF. Photographic elements should be high-resolution raster images, typically 150–300 pixels per inch at the final size, depending on viewing distance.

Working at scale presents practical challenges since few designers have monitors large enough to view 3-meter graphics at actual size. Many professionals work at a reduced scale using consistent ratios—designing at 1:10 or 1:4—and then scaling up for output. This approach works well provided you test that fonts, logos, and key information remain legible at the intended viewing distance. A headline that looks bold at 10% scale might appear thin and weak at full size.

Practical layout considerations differ from small-format work. Safe areas keep critical content away from edges that may be trimmed or covered by mounting hardware. Bleed extends artwork beyond the trim line to prevent white edges if cutting is slightly off. Copy should be limited for quick comprehension—viewers passing a banner at walking speed cannot read paragraphs of text. A strong contrast between text and background ensures visibility across varied lighting conditions.

Font selection matters more at a large scale than in documents. Fonts with clear letterforms and consistent stroke widths maintain legibility when enlarged. Thin or decorative fonts that look elegant in brochures may become illegible when scaled up and viewed from a distance. Testing color combinations on calibrated screens or small proof prints before committing to large runs avoids expensive reprints when colors shift unexpectedly.

Indoor vs Outdoor Large Format Printing

Where a print will be displayed directly affects every decision from materials and inks to finishing and installation hardware. Indoor and outdoor environments present fundamentally different challenges that influence how print media performs over time.

Indoor applications prioritize visual quality and print media characteristics suited for close viewing. Smoother finishes allow fine details and subtle gradients to shine. Accurate color reproduction matters more when viewers can examine prints at arm’s length. Paper, fabric, and lightweight rigid substrates work well in controlled environments without weather exposure. Short-term promotions might use unlaminated paper posters that cost less and are easy to recycle after a two-week campaign.

Outdoor requirements shift the priority toward durability and weather resistance. UV-resistant inks prevent fading from sunlight, which can quickly destroy indoor-grade prints. Weatherproof substrates like vinyl and mesh withstand rain, wind, and temperature fluctuations. Strong fixings, reinforced grommets, and welded hems prevent tearing when wind creates stress on large surfaces. Lamination or protective coatings provide an additional layer of protection against scratching, graffiti, and environmental contamination. These outdoor applications must maintain high visibility for months or years, not just weeks.

Consider the contrast between an outdoor festival banner and an in-store sale poster. The festival banner needs robust eyelets spaced every 500mm, reinforced hems along all edges, and UV-laminated vinyl that can handle rain and direct sunlight for a weekend event in variable conditions. The in-store poster, by contrast, can use a lighter paper stock without lamination, since it will hang for two weeks in a climate-controlled retail space before removal. Matching specifications to the environment ensures cost-effective purchasing without sacrificing performance.

Finding and Working with a Large Format Print Provider

Partnering with an experienced print vendor helps ensure that size, material, and budget decisions align with your project goals. The right provider brings technical expertise, equipment capabilities, and workflow efficiency that translate into better results and fewer headaches.

Key selection criteria include: capability to handle your required widths and quantities, range of materials offered, print quality and resolution, finishing options (lamination, mounting, cutting), turnaround times, and evidence of similar past projects.

When evaluating large-format printing services, request samples of work similar to your project. A provider specializing in vehicle wraps may not have the color-management expertise required for gallery-quality photography. A technical plotter shop focused on AEC drawings may lack experience with promotional graphics. Matching provider strengths to your needs avoids disappointing results.

Prepare print-ready files when possible to streamline production and reduce costs. Files should be at the correct dimensions, include proper bleed, use appropriate color profiles, and have fonts converted to outlines or embedded. Many providers can assist with layout, prepress checks, and color management for an additional fee, but preparation work done in advance speeds turnaround and reduces revision cycles.

For color-critical or high-value jobs, request proof samples or test prints before committing to full production. A small proof on the actual substrate with the actual inks shows how colors will appear in the final output and allows adjustments before high costs are incurred. Clarify expectations on deadlines, delivery methods, and installation services where relevant. Some providers offer end-to-end service, including installation, while others deliver finished prints for you to install independently.

Large Format Printing Conclusion

Large format printing enables oversized, high-impact graphics across indoor and outdoor spaces, supporting everything from shopfronts and trade show displays to long-term outdoor signage. The technology transforms blank walls, windows, vehicles, and exhibition stands into powerful brand communication tools that attract attention and create lasting impressions.

Understanding the terminology—large-format versus wide-format—and the applications, materials, and basic design principles helps you brief printers more effectively and achieve better results. Whether you need vinyl banners for your next project, window graphics to grab attention, or durable outdoor signage for year-round exposure, the fundamentals remain consistent: high-resolution files, appropriate materials, and a provider with the right equipment and expertise.

With the right provider and planning, businesses of all sizes can leverage large-format printing for cost-effective, highly visible branding and communication. Start by defining your project requirements, researching providers with relevant experience, and requesting samples before committing to production. The investment in proper planning pays dividends in high-quality results that serve your marketing goals.

(678) 235-3464

No comments:

Post a Comment