What is UV printing? It's a cutting-edge digital technology that cures ink on

the spot using UV light. This process results in durable, vibrant, and precise

prints, giving it an edge over traditional printing. Learn about its workings,

advantages, and why it's reshaping the printing landscape.

Key Takeaways

-

UV printing uses ultraviolet light to instantaneously cure ink, resulting in

prints that are highly detailed, vibrant, and durable, making it superior to

traditional printing methods in terms of speed and quality.

-

The versatility of UV printing technology enables it to print on a wide

array of materials, including paper, plastic, glass, metals, and unusual

substrates, while providing eco-friendly benefits such as almost no VOC

emissions and energy-efficient curing systems.

-

Continuous advancements in UV printer capabilities, ink formulations, and

curing systems have expanded the application of UV printing, enabling

high-quality personalization on objects and commercial/industrial use while

improving environmental sustainability.

Unveiling the Basics of UV Printing

UV printing revolutionizes the printing industry. By employing ultraviolet

light, this advanced technology facilitates the instant curing of UV inks on

the material's surface, which prevents ink from spreading and assures fine

details. The result? Prints that are rich in detail, vibrant in color, and

resistant to wear and tear.

Quite a leap from traditional printing methods to digital printing, wouldn't

you agree?

The Role of UV Light in Printing

UV light plays a pivotal role in the UV printing process. But how exactly does

it contribute to the printing process? It's simple: UV light interacts with

special photoinitiators in the UV ink, triggering a chemical reaction that

leads to the curing and hardening of the ink when exposed. This means that as

soon as the ink is printed onto the substrate, it's cured instantaneously,

ensuring sharp detail and preventing the ink from spreading.

A major advantage of UV printing is that the UV lamps used are typically:

- Energy-efficient LED lamps

- Ozone-free

- Require no warm-up time

- Cost-effective

Indeed, it's a win-win situation!

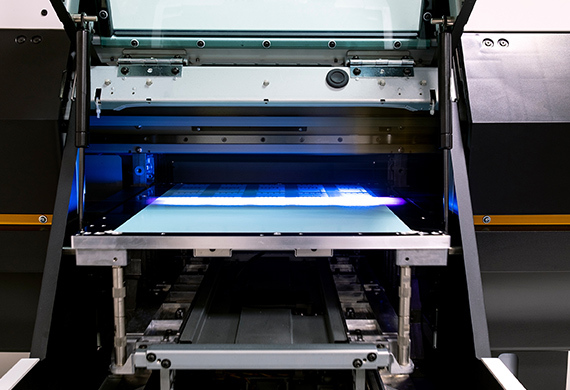

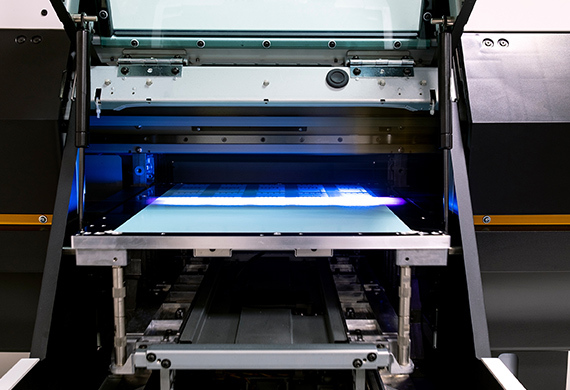

From Liquid to Solid: The Curing Process

A significant aspect of UV printing is the curing process. It involves a

photochemical reaction that instantly transforms liquid ink into a solid

state, facilitating immediate handling of the printed materials. UV curing, as

this process is known, employs high-intensity UV light to instantaneously

convert inks, coatings, or adhesives from liquid to solid state via

polymerization. The curing of UV inks involves a chemical reaction where

photoinitiators within the ink are activated by UV light to quickly harden the

ink without the need for heat or evaporation.

This instant curing of UV inks allows for immediate handling and use of the

printed material, which is a notable benefit over traditional drying methods.

In short, the UV curing process allows for a quicker turnaround in the

production of printed materials, making UV printing a swift and efficient

solution.

Comparing UV Printing to Traditional Methods

Despite the merits of traditional printing methods, UV printing offers several

distinct benefits:

-

It's exceptionally versatile and can be used for a wide variety of jobs,

including branding and creating luxurious business cards.

- It is especially effective on unusual or uncoated materials.

-

The instant curing process of UV printing ensures a crisp design without

imperfections and potential smearing or smudging, which is a common issue

with offset printing.

All these benefits make UV printing an excellent choice for projects that

require accuracy, speed, and versatility.

The Inner Workings of a UV Printer

Having touched upon the basics of UV printing, we will now investigate the

machinery that powers it—the UV printer. These advanced devices employ piezo

print head technology for precise ink placement. In fact, piezo print heads

eject ink with precision onto the print media, giving control over print

quality, color density, and finish.

But that's not all there is to it. Let's explore some of the other components

and processes that make UV printing possible.

Piezo Print Head Technology Explained

Piezoelectric print heads are at the heart of UV printers, and they play a

crucial role in creating high-quality prints. These print heads utilize the

piezoelectric effect, converting mechanical stress into electric fields to

form and place ink droplets accurately. Piezo actuators within these print

heads alter their shape in response to voltage, generating the mechanical

pressure needed to eject precise volumes of ink. Electronics within the print

head strategically manage timing and voltage to piezo actuators, ensuring

precise control over ink droplet size and shape.

The ink delivery system, where the printer distributes ink, includes a

reservoir and a network of channels and nozzles that efficiently guide ink

onto the printing surface, aided by a damping system to mitigate

high-frequency energy. This precision and control over the deposition of ink

contribute significantly to the quality and sharp detail of UV prints.

Navigating the UV Printing Process

The UV printing process involves a well-coordinated series of steps, each

contributing to the quality of the final product. Some of these steps include:

-

Ensuring that the glass substrate is free of contaminants; it may undergo

flame treatment and a primer application to enhance adhesion.

-

Precise control of ink droplet size and shape, which is crucial and managed

by electronics.

- Fast curing with ultraviolet lights.

These steps help to ensure a high-quality UV printed product.

A test print should be carried out before full-scale production to verify

design accuracy and printer settings, ensuring high-quality UV printed

products. To counteract the warping and bending of materials during UV

printing, securing the substrate through clamping or a vacuum bed is applied.

From substrate preparation to final inspection, UV printing requires a keen

eye for detail and meticulous execution.

The Instant Cure Advantage

As soon as UV inks are exposed to ultraviolet lights, they dry almost

instantaneously, eliminating wait times for ink drying or curing, and

enhancing detail in the print by preventing ink spread and distortion. This

instant UV curing process reduces the overall turnaround time of printing jobs

by around 40%, significantly speeding up production cycles without

compromising print quality.

But that's not all—UV printing also provides environmental benefits, thanks to

almost no VOC emissions, making it a more eco-friendly printing solution that

contributes to waste reduction and is safe for plant operators. Furthermore,

the adoption of LED UV lamps in instant curing systems is highly

energy-efficient, cost-effective, ozone-free, and requires minimal

maintenance, which contributes to lower operational costs.

In a nutshell, the instant cure advantage of UV printing offers a trifecta of

benefits: speed, eco-friendliness, and cost-effectiveness.

The Versatility of UV Printing on Various Materials

The versatility of UV printing is truly magical. This technology isn't just

for paper—it can handle a wide variety of materials, including:

- traditional substrates like paper

- non-traditional ones such as foam board, aluminum, and acrylic

- coated and uncoated materials

-

advanced materials like silk, embossed linen effect paper, and thick

triple-layered card

The unique property of UV ink to sit on top of the substrate without

penetrating it, combined with instant curing, allows for printing on a wide

range of surfaces. UV LED machines showcase the technology's breadth.

Plus, the versatility of UV printing supports environmentally friendly

practices by allowing the use of recycled paper or biodegradable materials for

signage, emphasizing sustainability. Let's delve deeper into how UV printing

makes its mark on various materials.

Beyond Paper: Printing on Nonporous Surfaces

Unlike traditional printing methods, UV printing isn't confined to porous

surfaces like paper—it can print on a variety of nonporous materials,

including plastic, glass, and metals. When UV printing on nonporous metal

surfaces, it's crucial to use high-quality printers and inks to achieve

durable and full-color prints. Even glass, with its smoothness and

nonporosity, can be successfully printed on with the appropriate techniques

and equipment.

LED UV curing technology is particularly advantageous for printing on

nonporous and heat-sensitive substrates like plastics, as it operates at lower

temperatures to avoid material distortion. What's more, UV LED curing ensures

that ink remains on the surface of printing materials without being absorbed,

resulting in sharper colors and more defined images. Applying specialized

surface finishes to UV printed metal parts can provide protection, chemical

resistance, and enhance the appearance with a shiny finish.

So, whether it's a glossy brochure or a metal sign, UV printing can handle it

all.

Embracing Diversity: Wood, Leather, and More

UV printing doesn't just work on nonporous surfaces—it also accommodates a

wide variety of materials. From wood to leather, UV printing allows for the

creation of vibrant, intricate designs that maintain high detail and color

accuracy. However, these materials may require special pre-treatment to

enhance ink adhesion and ensure the durability of the print. The type of UV

ink used for printing on wood and leather surfaces depends on the specific

nature of the material—whether it's hard, soft, or requires flexibility.

Even a range of leather and synthetic alternatives like PU leather,

leatherette, and Piñatex are compatible with UV printing, offering diverse

options for printing detailed graphics on different leather goods. To achieve

high-quality prints on darker leather materials, UV printing employs white ink

technology to lay down a solid basecoat, optimizing color vibrancy and detail

fidelity.

The versatility of UV printing opens up a world of possibilities for printing

on diverse materials.

The Advantages of Choosing UV Printing

UV printing offers numerous benefits, making it an outstanding choice for

various situations. Some of the benefits of UV printing include:

-

Enhanced durability: The cured ink is resistant to scuffs, marks, fading,

and moisture, making printed items last longer without the need for

lamination.

-

Cost savings: The energy-efficient UV LED technology used for instant curing

contributes to cost savings and requires minimal maintenance.

-

Versatility: UV printing can be easily integrated into various production

lines and provides customization options to meet diverse customer needs.

These advantages make UV printing a popular choice in the printing industry.

Overall, UV printing stands out for its advantages, and one of the most

notable benefits is the use of UV print technology, which results in low

emissions of volatile organic compounds (VOCs), making it a more

environmentally friendly option. Let's delve deeper into these advantages.

Eco-Friendly Printing Solutions

Given the growing focus on sustainability, the environmentally friendly

feature of UV printing is a substantial advantage. UV inks solidify instantly

under UV light without releasing volatile organic compounds (VOCs), in

contrast to traditional inks that emit harmful solvents during drying. Even

better, there are UV inks available that have low VOC content and UV-printing

processes that have been certified by standards like GREENGUARD GOLD, ensuring

lower emissions and suitability for use in sensitive environments.

The shift from traditional mercury lamps to LED UV curing systems has

increased energy efficiency, further reducing the environmental footprint by

minimizing CO2 emissions and hazardous waste. This makes UV printing not just

a superior choice for quality, but also a responsible choice for the

environment.

Achieving High-Quality and Vibrant Prints

In terms of quality, UV printing is unrivaled. UV inks contain up to twice as

much pigment as conventional inks, which enables richer color density and

vibrant print outputs without the colors sinking into materials. UV inks are

noted for their enhanced durability and fade resistance compared to

conventional offset inks, making them ideal for outdoor applications and

products subjected to sunlight.

Recent advancements in UV inks, such as wider color gamuts and the

introduction of additional colors like red and orange, have been central to

achieving more vibrant and high-quality prints. UV printer manufacturers

continue to enhance the image quality, color, and production capabilities of

their devices, contributing to the overall improved performance of UV printing

technology. Whether it's a luxury brochure or a vibrant poster, UV printing

ensures that the final product conveys a premium sense of quality through its

visual presentation.

Speed and Efficiency in Production

UV printing is not only about quality but also about speed and efficiency. UV

printing technology has seen recent advancements, including:

- Faster printing speeds which streamline the production process

-

The incorporation of UV-LED curing technology in UV printers allows prints

to be dried and ready immediately, facilitating quicker job turnover and

increased project capacity

-

Faster drying times with UV printing make it cost-effective by removing the

need for additional aqueous coatings to protect the print.

Compared to traditional printing processes, UV printing offers several

advantages:

- More production flexibility

- Reduced overhead costs

- Speedy and efficient

- Cost-effective solution for a wide range of applications

Innovative Applications of UV Printing Technology

The versatility and quality of UV printing have paved the way for its usage in

a broad range of innovative applications. From personalizing everyday objects

to commercial and industrial uses, UV printing has proven to be a versatile

and effective solution. It allows for detailed customization of small consumer

items like phone cases, with intricate designs and a full spectrum of colors.

Artists and designers have adopted UV printing to create bespoke artworks and

unique crafts that showcase high-resolution graphics and textures.

Personalized gifts, such as photo-printed accessories and monogrammed items,

take on a new level of quality and durability with UV printing.

Commercial industries use UV printing for a variety of purposes, including:

-

Creating eye-catching product packaging that resists fading and can

incorporate special effects such as embossing and gloss finishes

-

Producing long-lasting labels and functional components that must withstand

harsh environments

-

Decorative purposes, including interior design elements and custom furniture

printing

Let's take a closer look at some of these innovative applications.

Personalizing Everyday Objects

Picture your favorite quote, a beloved photograph, or a unique design on your

phone case or water bottle. UV printing can turn this vision into reality. UV

printing technology allows for the customization of:

- Water bottles with full color, gradients, and even textures

-

Personalized water bottles that feature designs utilizing variable data such

as names or numbers

-

Water bottles that achieve seamless full wraps with special effects like

spot varnish or texture

- Clear bottles that have mirror printing for double-sided visibility

With UV printing, the possibilities for personalized and unique water bottles

are endless.

UV LED printers are capable of customizing phone cases with a variety of

designs using materials like Poly Carbonate, ABS, Leather, and Silicon. Even

glass objects such as wine bottles can be enhanced with UV printing, with

accessories like a rotary jig ensuring stability and precision during the

printing process. From phone cases to wine bottles, UV printing can

personalize everyday objects in unique and vibrant ways.

Commercial and Industrial Uses

UV printing has found widespread applications in the commercial and industrial

sectors. This technology is utilized for creating a variety of signage and

advertising materials including flyers, leaflets, and signs, demonstrating its

adaptability across different media. For industrial and commercial branding,

UV printing on metal is employed to produce items like warning signs, barcoded

machine parts, serialized items, and labels for metallic packaging,

emphasizing its utility in durable and permanent marking.

Professionals also prefer UV printing to create traditional graphics such as

signage and posters, as well as vibrant in-store displays and point-of-sale

products designed to attract consumer attention. Even the packaging industry

has benefited from the progress in UV printing, with new ink formulations

enhancing printing on flexible packaging films and an increased number of

heat-sensitive substrates. It's clear that UV printing has a significant role

to play in commercial and industrial applications.

UV Printing: A Tool for Creatives and Entrepreneurs

For creative professionals and entrepreneurs, UV printing presents a world of

opportunities. This technology opens up new possibilities for creatives to

print with a vast array of vibrant colors and textures on various materials.

The ability to print on three-dimensional objects expands the scope for

designers to innovate with custom decor, signage, and unique product

enhancements. Creative professionals can leverage UV printing to produce

highly customized and limited-edition art pieces, leveraging its ability to

print on differing shapes and materials.

On the other hand, entrepreneurs have the opportunity to start new ventures or

expand existing ones by adopting UV printing due to its versatility and the

added value it brings to printed products. UV printing technology can give

businesses a competitive edge with the capability to offer rapid prototyping

and bespoke manufacturing services. It's become increasingly popular in

various industries, including promotional goods, packaging, and interior

design, due to its durability and high print quality. Physical retail

businesses can utilize UV printing to create eye-catching in-store displays

that enhance the customer experience and drive sales.

Let's delve deeper into how creatives and entrepreneurs can utilize UV

printing.

Crafting Unique Products

UV printing allows for:

- Quick adaptation to consumer trends

- Catering to individual preferences

- Creation of custom items for events and special occasions

-

Compatibility with a wide range of substrates, including both rigid and

flexible materials

This enables artists to craft highly individualized and unique product

offerings to meet diverse customer requests.

Artists and designers can cater to the interior design market with custom

products such as ceramic tiles and tabletops, as well as personalized gifts

like high-definition photographs and graphics on acrylic blocks, canvases, or

keyrings. UV printing expands business opportunities for artists by enabling

them to diversify their product range with promotional items like golf balls,

tumblers, and coasters and engage in the packaging market through unique and

eye-catching designs.

Creating unique products allows artists to make a lasting impression on their

clients and distinguish themselves from competitors.

Business Opportunities with UV Printing

UV printing offers a plethora of business opportunities for entrepreneurs.

This technology creates new revenue opportunities in the B2C sector through

the online sale of personalized products, catering to customers' preferences

for unique items. Entrepreneurs can leverage UV printing to meet B2B demand

for branded promotional items like pens and USB drives, which require

high-quality prints and accurate color representation for brand consistency.

UV printing's capacity for small-scale production allows businesses to

manufacture custom packaging and limited edition products efficiently, adding

value and increasing profit margins.

By targeting niche markets with UV printing, entrepreneurs can develop

specialized offerings for the travel and tourism sector, holiday-decorated

items, and personalized healthcare products, each providing avenues for

distinct and memorable branding. In this way, UV printing can help

entrepreneurs reach new markets, satisfy customer demands, and grow their

businesses.

The Evolution of UV Printing Technologies

Since its initial application in curing gel nail polishes, UV printing

technology has evolved significantly. Today, it's found diverse applications

in commercial and industrial printing, thanks to significant advancements in

ink formulations and printer capabilities.

For example, the Epson SureColor V7000, a new UV printer model, features a

10-color ink system including:

- red ink

- gray

- opaque white

- varnish

This substantially expands the color gamut and enhances the print quality.

This evolution in UV printing technologies has not only improved the quality

of prints but also expanded the range of possible applications.

Next-Gen Flatbed UV Printers

The emergence of next-generation flatbed UV printers, including the UV inkjet

printer, has further expanded the possibilities of UV printing. The Epson

SureColor V7000 introduces an entry-level UV flatbed printer with a 10-color

ink technology, while the IU-1000F UV-LED High-Productivity Flatbed Printer

offers direct printing onto 4' x 8' media boards. These new models, like the

Epson SureColor V7000 with its expanded color gamut and Roland's TrueVIS LG

Series with two new staggered printheads, offer enhanced print quality and

superior color definition.

Specialized UV printers like the Mutoh XpertJet 661UF allow for rotary

printing on cylindrical objects, while the VersaUV and VersaOBJECT series

cater to a wide variety of substrates and print sizes. As you can see, the

advancements in flatbed UV printers have significantly broadened the scope and

potential of UV printing.

Breakthroughs in UV Inks and Curing Systems

In addition to advancements in printer technology, significant progress has

been made in UV inks and curing systems. LED UV printing technology is more

environmentally friendly than traditional methods, utilizing significantly

less power and eliminating the need for heat in the drying process, thus

reducing its carbon footprint. UVLED curing enhances the process by

implementing Pulse-Width Modulation (PWM) technology, allowing curing power to

be adjusted to different speeds, minimizing potential damage to substrates.

Some benefits of LED UV printing technology include:

- Reduced energy consumption

- Faster drying times

- Improved print quality

- Increased durability

- Compatibility with a wide range of substrates

These advancements in UV inks and cure ink systems have revolutionized the

printing industry, including inkjet printers, providing more efficient and

sustainable printing solutions.

Recent breakthroughs in UV ink technology have introduced expanded color

gamuts and the development of semi-flexible inks, which provide superior print

quality and more dynamic color ranges. These innovations have not only

improved the performance of UV printing but also its sustainability and

versatility.

UV Print Summary

As we've explored, UV printing is a revolutionary technology that offers

numerous advantages over traditional printing methods. From its ability to

print vibrant, high-quality images on a variety of materials to its

environmental benefits and cost-efficiency, UV printing is truly a

game-changer. Whether you're an artist seeking to create unique masterpieces,

a business looking to offer personalized products, or an industry professional

in need of durable and vibrant prints, UV printing has something to offer. As

UV printing technology continues to evolve and innovate, we can only expect it

to open up even more exciting possibilities. So, are you ready to embrace the

future of printing with UV technology?

Frequently Asked Questions

These are the most common questions about UV printing:

What does UV printing do?

UV printing, also known as Ultra Violet Printing, uses UV curing ink to print

on a wide range of materials or substrates. It offers versatility in printing

options.

What is the difference between UV printing and normal printing?

The main difference between UV printing and normal printing is that UV inks

dry through a photo mechanical process with the use of Ultraviolet light,

rather than being absorbed like conventional ink. This results in instant

drying of the ink as it is printed.

How long does UV printing last?

UV printing can last at least two years without fading, and with lamination,

it can last even longer.

Is UV printing the same as sublimation?

No, UV printing is not the same as sublimation. UV printing is a single-step

process where the ink dries instantly with built-in UV light, while

sublimation is a two-step process that requires external heat for drying,

making it relatively time-consuming.

How does UV light contribute to the printing process?

UV light contributes to the printing process by triggering a chemical reaction

in UV ink, leading to its curing and hardening, which ensures sharp detail and

prevents ink from spreading. This enhances the printing quality and accuracy.

Clash Graphics Print Shop Atlanta Flyer Printing

2233 Peachtree Rd NE Ste 202 Atlanta, GA 30309

(678) 235-3464

To view the original version on Clash Graphics, visit: https://www.clashgraphics.com/printing-tips/what-is-uv-printing/